Dry Chemical Fire Suppression System

Dry chemical fire suppression system. Dry Chemical Fire Suppression Systems provide 247 fire protection for industrial process equipment in applications ranging from paint spray booths to generator rooms to flammable liquid storage containers. Often found in a variety of industrial settings dry chemical systems provide flexibility based on the size and configuration of the application. Dry Chemical Fire Suppression System.

These agents quickly suppress the fire without harming the. Over the last few years there have been questions about changing an existing dry chemical extinguishing system to a listed UL 300 wet chemical system. Sodium bicarbonate also known as baking soda combines with an.

Best suited to protect these hazards is an industrial dry chemical fire suppression system designed for local application or total flood utilizing ABC or BC dry chemical. The Dry Chemical Fire Suppression Systems provide excellent fire coverage. What is a Dry Chemical Fire Suppression System.

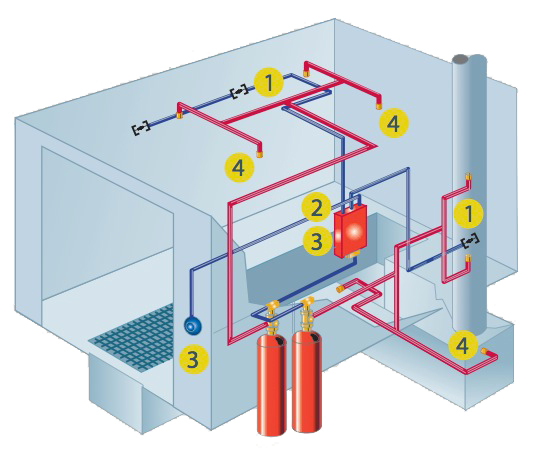

They can also be activated manually through fusible links. Systems contd Three categories of agents. The A-101 Fire Suppression System is an.

The system shall consist of Kidde IND Dry Chemical storage Cylinders Kidde XV Control System Kidde actuation hardware and Kidde agent distribution nozzles attached to a pipe network. Gas station fire suppression systems often deploy a sodium bicarbonate-based dry-chemical agent. Dry Chemical Fire Suppression Systems consist of dry chemical compounds that suppress fire effectively because they are easy to install in any industrial setting.

If and when temperatures drop below freezing the pipes are not in danger of freezing as they are with their wet sprinkler system. The hazard being protected has changed. This article entails everything you need to know about dry chemical systems.

Dry Chemical Suppression Systems. Our dry chemical fire suppression systems are UL ULC listed and FM approved and include fusible link detection for automatic actuation as well as a manual pull station that allows you and your team the ability to control possible chemical fires with multiple nozzles intended for total flooding application.

Fixed dry chemical extinguishing.

Description Dry chemical fire suppression systems have several key advantages over water-based solutions for a wide range of applications. Sodium carbonate based Class B and C fires Potassium based Class B and C fires Multipurpose Class A B and C fires Agents are generally nontoxic but. Sodium bicarbonate is for Class B and some Class C fires. Best suited to protect these hazards is an industrial dry chemical fire suppression system designed for local application or total flood utilizing ABC or BC dry chemical. Most are Pre-engineered due to the standard size of paint booths and mixing rooms. Updating your fire suppression system should be considered if any of the following has occurred. This system is effective by flooding a volume of space. This article entails everything you need to know about dry chemical systems. What is a Dry Chemical Fire Suppression System.

Often used in cases where water will not adequately extinguish flames these systems pour a. Monoammonium phosphate is for ABC fires. A dry chemical fire suppression system is a type of fire protection system that makes use of a dry chemical powder to extinguish a fire. Gas station fire suppression systems often deploy a sodium bicarbonate-based dry-chemical agent. Dry chemical systems can be actuated either electrically or mechanically fusible links which makes it a good choice for harsh environments. You must recharge them after every operation. Often found in a variety of industrial settings dry chemical systems provide flexibility based on the size and configuration of the application.

Post a Comment for "Dry Chemical Fire Suppression System"